Naim Power Amps: mods and upgrades

this page and links generously contributed by Ced Taylor, Jan 2009: www.acoustica.org.uk (opens new window)

| Poweramps: Mods and Upgrades |

| The following is a list of mods compiled from around the internet, principally contributors to pink fish media, neil mcbride and avondale audio. |

| All comments and opinions are mine. They are meant as guidelines only and other opinions, information and experiences are gratefully received (contact details below). Saying that, something is probably very wrong if you're getting no joy out of the mods. |

| None of the information below is in anyway an endorsement of the modifications involved and no responsibilty can be taken for any consequences whatsoever of attempting them. Check parts against datasheets and schematics also to be safe- I have made more than one typo in my life. Best know what you're doing before trying them as power amps are particularly merciless with feck-ups and dodgy soldering etc. No nice DC blocking caps and low currents to save your equipment and self. Basically you take responsibility for your own actions comrades so use a bit of judgement. Cheers, Ced. |

| Naim Amplifiers |  |

|

|

|

| Nap 160 | Nap 250 | Nap 135 | Nap140 psu |

|

|

|

|

|

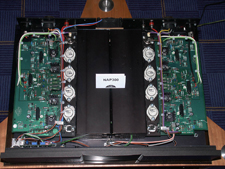

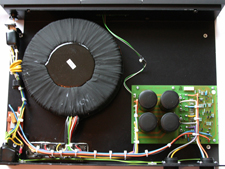

| Nap 250-2 (composite pic) | Nap 300 amp | Nap 300 psu | Nap500 amp |

| Regulator boards (Nap 250) |  |

|

| Nap 250 regulator board(fig5) | regulator schematic (fig 6) |

| other mods | ||

|

|

|

| output transistor decoupling (fig 8) | output transistor decoupling schematic (fig 9) | |

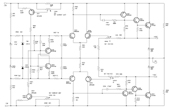

| circuit descriptions | |

|

Amp descriptions:

|

The essential amp circuit remains the same for all Naim poweramps for a series though there are the original and the '500' versions. The orignal versions cover the chrome bumper and olive fascia series. The 500 version boards are in the brushed aluminium fascia series. For

original models, the essential difference between a Nap140

and

a

Nap

135 is in the

quality

of the

power supply and the power delivery. For

new 500 series models, the difference I believe (and I may be wrong),

between the lower Naps and a Nap 500 is still in the quality of the

power

supply

and

the

power

delivery. The 500 has comparatively much more sophisticated

power supplies and is a bridged topology [using 2x modified NAP ciruits on each channel- MC]. |

| Regulator board descriptions | Pretty

simple discreet power opamp design and essentially very crude-

fig 6. Based on an old old design by Anthony Holton if an old schematic

and notes don't deceive me. Doesn't take much to jazz this up e.g.

decent

current

source

at the base

of the long

tailed

pair, decent voltage reference, filtering and internal regulation

etc. This was done by someone a few years back (current source anyway)

who

made favourable comments of the results. Reports

are

generally

that

the

regulator

is responsible for the slightly 'darker' and more detailed sound

of the old 250 upwards but also damped the dynamics somewhat? It

also has

current

limiting

circuitry which puts a fat bit of impedance

(0.1ohms) on the power rails and is generally not a good idea sound

wise imo, which might have been responsible. Also its apparently

a bit of a noisy bugger so not that great performance though it probably

cleans

up

the rails

a tad.

[NB the 0.1 ohm series resistor is inside the feedback loop, so pretty insignificant as a component of dynamic output impedance in this regulator design - MC]

Historic rumours

would indicate the regulator boards were a good way of implementing

current limiting in what was essentially a studio design and needed

to be, above all, rugged to abuse by hairy muso types used to absentmindedly

sticking anything anwhere while fussing over faders and 'the top

end, Jerry'. And indeed old

reports

were that the 180 is a tad more dynamic than a 250. I've had or audititoned

all 3, and for my money would stick with a 140 and mod that if it

can drive your speakers happily. As stands I found bugger all worth

dropping a grand+ extra over between the three.

[For a more recent discussion of the NAP regulator design and some modification ideas, please see this recent Pink Fish media thread - MC, 23.01.09]

|

| Mod | Comments and information | Bang for buck | |||

| Basic Mods- Amp boards | These are all reasonably simpl | ||||

| 1 | upgrade input cap | upgrade

C1 form blue 10uf tant to a 1uf-3.3uf Evox SMR polyphynl sulphide

capacitor. Other caps are also viable- see preamp coupling caps section. |

1uf

SMRs will technically give a very slight bass rolloff but are easy

to fit. the rolloff is not audible. Oh no. 3.3uf is nice

but must be fitted with flying leads. 10uf doesn't harm either but not

necessary. |

5/10 | |

| 2 | Remove protection circuitry | Remove the following components: R6-R11, C6-C7, D1-D2, TR7-TR8. |

See

fig 3. This removes the overcurrent protection circuitry which apparently

significantly

muddies the sound. Haven't evaluated this mod on its own but

together with mods 1,2 and 3, 4 (electrolytics) it makes a definite

improvement. The macbride and avondale versions of the Naim amp board

do not have

this

protection circuitry either and its efficacy is considered suspect as

its main purpose is to protect the output devices from overload.

Worth

bearing in mind is that the new 500 series amps have much lighter protection

too. Neil McBride says:"Without

it, the amps are more powerful sounding, more transparent, and more involving

and musical." I

agree. Easy and reversible (with a dab of solder) is just to snip

one leg of D1, D2, R6, R7 and R10, R11 if you fancy being a bodger. |

5/10 | |

| 3 | Upgrade feedback cap | Upgrade

c2 (red tantalum cap)

In

the Nap140 this is 47uf, in the macbride and avondale NC200 it is 68uf

and in NAP 250s it is also 68 or 100uf . Voltage rating must be 6V

or higher,

generally higher rated caps sound better. |

Now

Ive done this with an elna silmic of the same value as a nice drop

in replacement. It makes

a nice little upgrade. |

11/10 | |

| 4 | upgrade VBE biasing decoupling cap | Replace

c3 (usually the red tantalum cap) with better of the same value. Les

W at avondale also recommends a 68uf BC128 solid aluminium cap. In the

Nap140 this is 47uf, in the macbride and avondale nc220 it is 68uf

and in NAP 250s

it is also 68. Voltage rating should be 16V or higher, generally higher

rated caps are better. |

not been evaluated independently but it would be rude not to do this while you're at it. I've used an oscon and now run a 47uf evox MMK. You'll need flying leads. I think anything above 10uf is considered good so try in the 10-68uf range- it basically irons out voltage variation in the biasing VBE. | ? | |

| 5 | upgrade direct signal path and feedback loop resistors | These

are R1-R5 on fig1. Replace with vishay dale RN 60 or Welwyn RC55y

or higher grade resistors. See 'Preamp

feedback loop resistor' section for alternative components |

Not

been evaluated in A/B comparision, but it didn't do any damage for sure.

|

? | |

| 6 | upgrade power resistors | Replace the power resistors R12-15, (fig 1) with Caddock MP930s. | Not

been evaluated in A/B comparision,

but it didn't do any damage for sure.

|

? | |

| 7 | output transistor decoupling caps | decouple

both+ve and -ve powerrails on each board with the highest possible

quality

caps (eg Rubycon ZL) 470uf, 50V (see fig 8) right

next to the output power transistors. Fig11. Rubycon ZLs soldered to output transistors under the boards. (Green wires are where an Evox MMk was removed so you can see). Note on the picture in mod 3, the 4 extra black wires going to star ground for the ZLs. |

See

fig 8 and 9. This was another big mod. I loved it. Just added more

power, authority, attack etc blah, imaging, highs, lows whatever. solder

capacitors C10 and C11 in fig8 to the correct pin of the output

transistors under

the boards (solder to the actual pins as the caps must be as close to

the transistor as possible) and run flying leads back to the star

earth

between the main psu reservoir capacitors NOT a 0V point on the actual

amp boards. Use at least 1mm2 wire for the OV return wires for a

good

low impedance connection. You only need to use 2 leads as per fig9 as,

as Martin says, 'there is no interaction between pairs of caps sharing

a return to the main 0v star point - this is a ClassB amp, so only one

half of the output stage conducts (and needs decoupling) at a time

under

load. Either

way results are an immediately noticeable increase in 'slam' and

weight

and a general tidying up of the sound- everything just sounds more lifelike. |

8/10 | |

So

with these mods you will have given yourself a new poweramp that I

would confidently expect to trounce a 250-2/300 in most respects

for a few quid and a bit of time. Your poweramp must be able to drive your speakers.

If its underpowered no amount of fiddling will compensate the lack

of drive power. A 140 with EPOS 22s for example sucks like a hoover

whatever

you

do.

|

|||||

| Mod | Comments and information | Bang for buck | |||

| More advanced Builds | |||||

| 1 | Build your own | Build the Avondale AZ260 amp |

This

is based on the the Naim amp circuit but more refined; with upgraded

components, tweaked power rails, no output protection circuitry and

some other circuit tweaks such as emitter degeneration on the input

pair and onboard output inductor- Avondale's NC200 poweramp boards.

Giving apparently a much more powerful, refined

and

musical

performance

. Avondale

also supply an apparently excellent CAP6 reservoir capacitor board,

and some very good low impendance toroid transformers. Not heard

one, but all those people can't be wrong- theres been pretty universal

praise for them. |

? All reports are highly favourable compared to Nap250/Nap135s | |

| 2 | Builda Neil McBride NAP Clone | Build

a macBride 250/135 clone |

Based closely on the nap250/Nap135 with a few refinements such as upgraded components and eliminating the overcurrent protection circuitry on the amp board. It runs with power regulator boards. Is it worthwhile going down this route? Yes, as a spring board if you want to DIY heavily, have plans for a very personal modified creation and will end up rebuilding it and ripping it apart serveral times, need a particular chassis layout, wish to try a NAP300 chassis arrangement etc. Basically i'd look at it as more a recipe idea whereas the avondale is a ready meal. Either way check Neil's website here as its still a very useful site even after all these years. Just looked again and its all getting very self referential around here now, heh.

|

? | |

| One can go further than the above mods to an existing amp but the law of diminishing returns kicks in powerfully (well, sort of) and you really have to build from scratch with plenty of space and a lot of time to try things out. Think of a poweramp as essentially a high voltage preamp with a high current output buffer stuck on the end and you won't go far wrong. | |||||

| Mod | Comments and information | approx cost | Bang for buck | ||

| Minor Mods/Servicing | These are all reasonably simpl | ||||

| 1 | Adjusting the output DC offset |

Les

W of Avondale has said: "for those who are looking for the

offset adjustment on Naim amps, there isn't any. The offset is determined

during manufacture

by the gain relationship of the two transistors forming the VAS (Voltage

Amplifier Stage) [TR1 & TR2 on fig 1] at the input of the amplifier.

Bench selection of these transistors during building assure the

offset

stays at a pre-determined level (10 - 30mV) during the life of the amp." ** measure

the voltage between points B & C in fig1 (the outputs)." |

? | ||

| 2 | Adjusting the bias (standing current) |

Make

sure no input nor speakers are connected to the poweramp. Personally

on my amp I solder a 10 ohm power resistor between the +ve psu supply and

the +ve power terminal of the amp board. its just a bit of extra insurance.

Aim for about 0.36V accross this

resistor. When

I'm there, desolder the resistor and resolder the supply direct to the amp

board. |

? | ||

| 3 | TR11 & TR12 OUTPUT TRANSISTORS |

These are TR11 & TR12 in fig1. Naim use custom NA001 transistors sourced from Semelab. However they are not deeply magical parts and alternatives are quite acceptable. Alternatives in TO3 cans that have been used as replacements are BUV20 at about £12 each and MJ15003 at £3. Both recommended by Les W. He states, and I paraphrase, that he considers the MJ15003 very very agile and informative but the BUV20s deliver the power and the glory. Neil mcBride recommends MJL3281a but these are T0264 flat packages and are only viable if building from scratch, probably using his boards. Not compared the three directly myself, Yet, but the MJLs are quite acceptable for sure. I wouldn't expect night and day differences in the grand scheme of things either way though. Old

NAP140s used to use Sanken 2SC2922 ouput transistors (see fig 3)

before

this was changed to the TO3 NA002 and NA001 transistors. still available,

just search the net. |

? | ||

| 4 | TR1 & TR2 INPUT PAIR | BC546 are fine here- High voltage variant of the BC550. They need to be matched to give an offset of up to 30mv. see avondale schematic for how to here. | ? | ||

| 5 | TR3 | BC546 are also fine here or MPSA06 have also been used. | ? | ||

| 6 | TR4 | ZTX753 | |||

| 7 | TR5 | 2N5551 | |||

| 8 |

TR6 |

ZTX653 | |||

| 9 |

TR7 DRIVER |

MJE15030 | |||

| 10 | TR8 DRIVER | MJE15031 | |||

| 11 | Reservoir caps | Kendeil

caps are VERY nice replacements for Nap 180 ,250, 135s or for use

in Mcbride amps . Get

from avondale, audiokit or a few other sources on the web. though

note they are large

so there

may

be

some

fiddling

and

ingenuity

involved in mounting. Alternatively try a cap6 board from Avondale

though not auditioned one myself. Reports are very good. |

|||

Wow! Thanks, Ced! - MC

If you have anything we can add to this page for the benefit of anyone interested, please contact Martin.

www.acoustica.org.uk (opens new window)